Flexible Manufacturing Systems

Our capabilities cover the varied needs of multiple industries. We work based on your top priority: if you need something on a shorter timeline, our pre-engineered solutions are the path to meeting your needs. If customization is your biggest concern, we can start from the beginning and craft a customized solution fit to suit.

Calvary serves many industries with our core markets being:

- Automotive/Transportation

- Healthcare/Medical

- Consumer Products

- Energy

- Food & Beverage

- Shipping & Logistics

- Agriculture & Cannabis

X-Cell II Series

The X-Cell II platform provides a unique capability by integrating proven automation components into a high-performance and flexible system. The system has the ability to accommodate a large number of assembly and related processes for a wide variety of products both quickly and easily. The platform can be utilized and validated at the process development stage and then scaled into production, eliminating the need to revalidate the process. This provides for unprecedented cost reductions and greatly reduced time to market. The control of the system is based upon simple and intuitive controls, therefore reducing the need for complex programming.

Key Features:

- Minimal Validation Efforts and Cost

- Modular and Re-deployable Systems

- Integrated Vision Inspection and Correction

- Array of Interlocked Guard Enclosure with Large Viewing Area

- Integrated Control Panel for all PLC, Motion Control, and Vision Hardware

- Scalability from Process Development Stage through to Production

- All Sides Access for Tooling and Parts Feeding

.jpg?width=300&name=Homepage%20Image%20-%20(Calvary%20Robotics%20Platforms%20-%20X-Cell%20Series).jpg)

%20(1)%201.png?width=300&name=Solutions%20Image%20-%2001%20(X-Cell%20II)%20(1)%201.png)

X-Cell II

X-Cell II

The smallest form factor of our standard chassis. This X-Cell II footprint provides unmatched flexibility and scalability.

.png?width=300&name=Solutions%20Image%20-%2002%20(X-Cell%20II%20Plus).png)

X-Cell II Plus

X-Cell II Plus

The X-Cell II Plus is our medium form factor chassis allowing the same flexibility as our standard X-Cell II, with added tabletop space for multistep process points.

.png?width=300&name=Solutions%20Image%20-%2003%20(X-Cell%20II%20Double).png)

X-Cell II Double

X-Cell II Double

The X-Cell II Double is our largest form factor chassis, allowing for multi-zoned processes under one chassis. Perfect for complex systems running multiple product models.

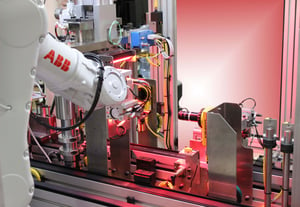

Flex Feeding Automation

Flexible Feeding and Sorting Systems offer AB ControlLogix PLC with PanelView+ 1000 HMI and utilize Ethernet networks for process control & data communication. Further benefits include:

- Fully automated system, no operators needed

- Multiple part feeding methods available

- Simplified vision-guided robot part picking

- Parts assembly from both top & bottom

- Add modules via Plug & Play distributed controls

- Quick change part transfer tooling

- Part marking

Ready to Learn More About System Integration?

Our FREE guide "A Guide for Engineers Exploring System Integrators" is your first step into your automation journey with Calvary Robotics!

Custom Automation Solutions

When pre-engineered platforms can’t be customized to suit your needs, we can build an automated system.

Our experienced team handles projects that help scale your production operations to suit current demand. We provide recommendations based on the most up-to-date technologies and leverage our multi-industry experience to craft automation solutions. We prioritize long-term relationships so we can start where we left off when expansion is needed.

Some of our custom capabilities include:

- Motion platforms that carry the parts around

- Linear motor: state-of-the-art

- Precision link

- Dials

- Old-fashioned conveyors - moving products around

- Robots

.png?width=1330&height=503&name=NEW_Solutions_Image_-_04_(Flexible_Manufacturing_Systems).png)

.png?width=818&height=460&name=Solutions%20Image%20-%2005%20(Flexible%20Manufacturing%20Systems).png)

Flexible Manufacturing Systems

Our capabilities cover the varied needs of multiple industries. We work based on your top priority: if you need something on a shorter timeline, our pre-engineered solutions are the path to meeting your needs. If customization is your biggest concern, we can start from the beginning and create first generation prototypes to bring your vision to life.

Calvary serves many industries with our core markets being:

- Life Sciences

- Transportation

- Consumer Products

- Green Tech

- Industrial

.jpg?width=300&name=Solutions%20Image%20-%2006%20(Build-to-Print%20&%20Machine%20Replication).jpg)

Build-to-Print & Machine Replication

Build-to-Print & Machine Replication

Calvary offers Build-to-Print (BTP) services extending beyond our Design and Build options. These services cover machine replication for projects built by Calvary, the customer, or other engineering firms. We also provide design enhancements for existing equipment, addressing component obsolescence and creating new documentation packages. Our acceptance options range from inspections and I/O checks to full system operation. Additionally, we offer spare kits for both fabricated and purchased components, emphasizing long-term support and service.

.jpg?width=300&name=Homepage%20Image%20-%20(Calvary%20Robotics%20Platforms%20-%20Robotic%20Software%20Platforms).jpg)

Robotics Software Platforms

Robotics Software Platforms

Custom precision-crafted, validated software that maximizes automation ROI by elevating design quality and simplifying processes, implementation, support, and maintenance for the end user.

.jpg?width=300&name=Solutions%20Image%20-%2008%20(Machining%20&%20Fabrication).jpg)

Machining & Fabrication

Machining & Fabrication

We provide reliable and knowledgeable machining and fabrication solutions for customers worldwide. Our track record and dedication have created valuable, long-term relationships with our customers. This operates as a separate business unit and has built a solid foundation composed of outstanding machining, fabrication, and related services capabilities. We are your dependable partner for providing the best value and return on investment in the industry.

.jpg?width=300&name=Solutions%20Image%20-%2009%20(Product%20Lifecycle%20Management).jpg)

Product Lifecycle Management

Product Lifecycle Management

InTune Products provides high-technology solutions for our customers who are looking to commercialize products. The combination of services and offerings are unparalleled in the industry and result in reductions in cost, risk, and delivery while providing the scale necessary for success. Through a robust, disciplined, and proven staged process, we can provide all of the facets needed to bring your product or solution to the market.

Research & Development Labs

Research & Development Labs

Calvary has always and continues to reinvest in technology and human resources, along with our facilities and equipment. One of our latest investments with our technology partners is our research and test labs:

- Robotics

- Technology

- Vision

- Quality Inspection

Our labs are used for quality checks, project feasibility and risk reduction, as well as research and development surrounding the latest enabling and disruptive technologies.

Elevate your project with an expert one-on-one.

We are proud of the growing number of repeat customers and the partnerships that we have jointly created based on value, integrity, and trust.

.png?width=500&height=140&name=Calvary_Robotics_Logo-(500x140).png)