Robotic Automation Systems

Calvary Robotics is a world leader in designing, building, and developing custom turnkey automation solutions, robotics platforms, material handling systems, and a predominant integrator of third-party technology and equipment.

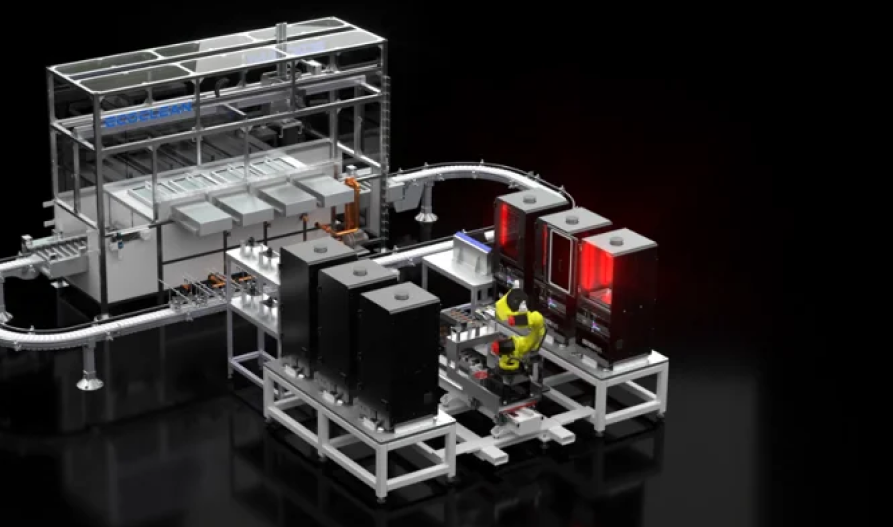

Flexible Feeding and Assembly Systems

Calvary Robotics software platforms bring turnkey automation solutions with an edge, allowing projects to be done quickly and correctly. Our Flex Feeding & Assembly capabilities are revolutionizing the assembly process. Utilize our pre-engineered manufacturing systems such as the turnkey X-Cell Series, or work with our team of expert engineers to design a custom robotic automation system that utilizes our established platforms. Experience versatility, reduced changeover time, improved efficiency, accuracy, cost-effectiveness, increased capacity, safety, and quality with our automation systems.

.jpg?width=300&name=Applications%20Image%20-%201%20(Flexible%20Feeding%20&%20Assembly).jpg)

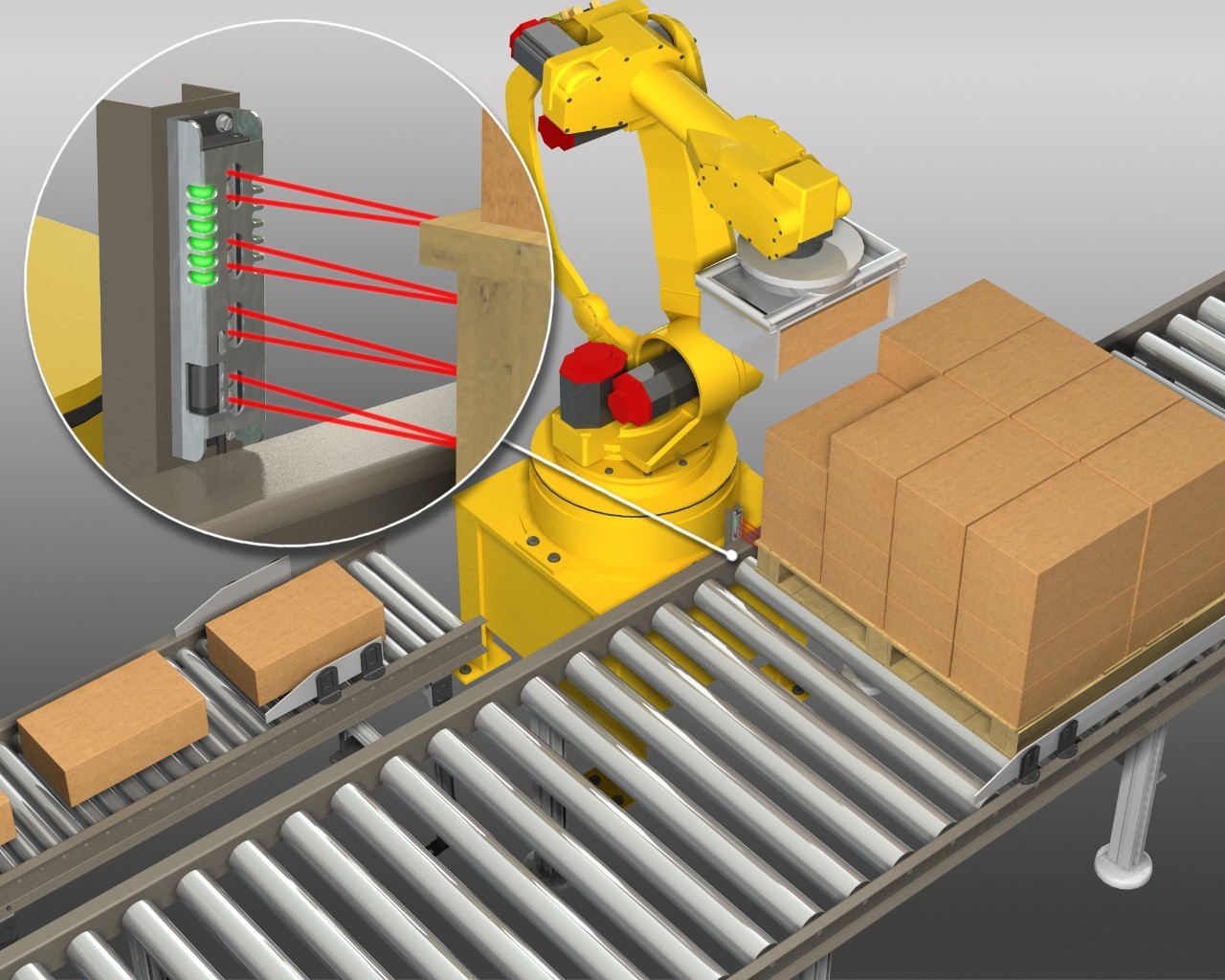

Material Handling and Palletizing

Material Handling and Palletizing Automation bring a level of safety and efficiency to your line of operations. Manual processes can slow down operations and be costly, dangerous, and lead to slower results. Together, these critical processes streamline operations, enhance employee safety, and boost productivity.

Calvary’s robotic palletizers reduce cycle time by quickly sorting, transferring, and stacking products. Discover how automation can increase efficiency through manufacturing, shipping and delivery.

Welding Automation

Calvary Welding Automation is a cutting-edge technology, transforming and propelling industries into a new age of efficiency, precision, and safety. The machinery performs welding tasks, removing the chance of human error. This approach enhances the speed, accuracy, and repeatability of welding processes, delivering superior results in terms of quality and cost-effectiveness.

%201%20(2).png?width=1330&height=537&name=Applications%20Image%20-%204%20(Welding%20Automation)%201%20(2).png)

.jpeg?width=1280&height=720&name=Applications%20Image%20-%205%20(Machine%20Tending%20Solutions).jpeg)

Machine Tending Solutions

Discover the future of industrial automation with Calvary Machine Tending Solutions. These automated processes handle, load, and unload equipment, ensuring seamless production every time. Our state-of-the-art systems are designed to systematically perform tasks varying from part loading to quality control.

The introduction of robotics in machine tending automation offers both speed and accuracy across numerous industries and applications. From faster tool changes to seamless unmanned production, objects can be loaded quicker while saving on valuable floor space through its compact design.

Automation in Manufacturing: A Revolution in Your Manufacturing

In this exclusive article, you'll learn the impacts automation integration has on productivity and efficiency and how systems can be customized to your current ecosystem.

.jpg?width=300&name=Applications%20Image%20-%207%20(Laser%20Automation%20Applications).jpg)

Laser Automation

Precision, power, and progress meet innovation with Calvary Laser Automation. Laser automation involves the integration of laser technology with automated systems to perform a variety of tasks, including laser welding, laser cutting, and laser marking. Harnessing the laser's precision and focused energy, these applications open doors to various industries while creating precision, traceability, contactless processing, and enhanced safety measures.

.jpg?width=300&name=Applications%20Image%20-%208%20(Testing).jpg)

Testing Automation

Tailored to propel your product capabilities, Calvary Testing Automation solutions provide precision, efficiency, and innovation. Our automated testing systems deliver products that meet stringent quality standards and deliver detailed data crucial for continuous improvement.

.jpg?width=300&name=Applications%20Image%20-%209%20(Packaging%20Automation).jpg)

Packaging Automation

Transform your efficiency with Calvary Packaging Automation. Designed for precision, speed, and reliability, our robotic systems revolutionize your packaging process delivering unparalleled efficiency and consistency. Experience enhanced productivity, reduced downtime, cost-effective operations, and more by automating your packaging process.

.jpg?width=300&name=Applications%20Image%20-%2010%20(Vision%20System%20Automation).jpg)

VISION SYSTEMS AUTOMATION

Calvary Vision System Automation utilizes sensors, software, and AI for applications including product and parts inspection, measurement, and classification. The 3D scanning sensors & perception capabilities allow the machines to make decisions based on visual data. By integrating our vision systems into your operation, there will be increased quality and productivity along with a reduction in errors and waste.

.jpg?width=300&name=Applications%20Image%20-%2011%20(Dispensing).jpg)

Dispensing Automation

Robotic Dispensing Automation increases the efficiency of your dispensing processes. The automatic robotic systems precisely dispense liquids, adhesives, sealants, or other materials. Calvary Robotics specializes in advanced dispensing automation solutions that ensure consistency, accuracy, and safety across all applications.

.png?width=500&height=140&name=Calvary_Robotics_Logo-(500x140).png)